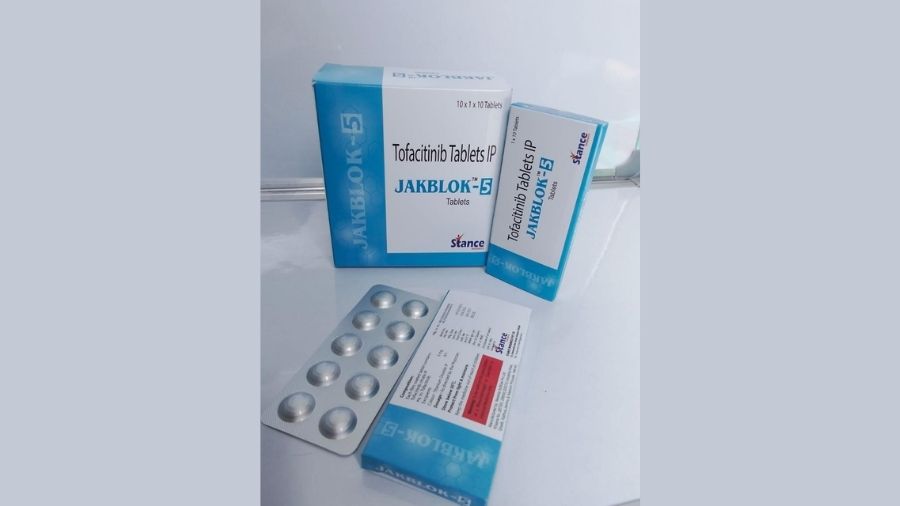

Tofacitinib Tablets IP – JAKBLOK-5 Manufacturing in India

India has become known as the “Pharmacy of the World” for its contribution to the healthcare sector by producing quality, affordable generic drugs. One of India’s most advanced pharma products is Tofacitinib tablets, which is classified as a Janus Kinase (JAK) inhibitor. Tofacitinib Tablets IP 5 mg are indicative of the industry’s best practices when it comes to drug manufacturing, as they reflect the level of specialized manufacturing facilities, well-defined quality control processes, and compliance with regulatory requirements.

When considering launching Tofacitinib under a brand name, pharmaceutical companies will frequently opt to use contract manufacturing in pharmaceutical industry to produce their brands, thus utilizing the expertise available at a Contract Manufacturer’s facility. In this model, the pharmaceutical company focuses on its marketing and distribution processes while relying on the qualified experience from Contract Manufacturers in India, including companies such as Medella Softgel or other leading medicine manufacturers.

Understanding Tofacitinib Tablets– The Role of a JAK Inhibitor

Tofacitinib is a potent agent for treating multiple autoimmune diseases such as severe to moderate rheumatoid arthritis, psoriatic arthritis, and ulcerative colitis.

- Mechanism of Action – Tofacitinib’s mechanism of action is through the selective inhibition of JAK (Janus Kinase) Enzymes. As JAK enzymes play a critical role in the inflammatory and immune response pathways within the body, inhibiting their activity will serve to achieve pain reduction and decrease swelling and damage to joints.

- Dosage Form – tofacitinib tablets 5 mg have primarily been manufactured in a tablet form, though Tofacitinib can also be compounded as an immediate-release formulation. The market is served mainly through this method due to its potency and the fact that the required dosage for a patient is low, thus requiring careful manufacturing processes in producing these pharma products.

The Tablet Manufacturing Process – Focus on Direct Compression

A complicated process governed by Good Manufacturing Practice (GMP) surrounds the manufacturing of Tofacitinib Tablets IP 5 mg because of the high potency of the API and the uniformity required in the very small tablet. As a result, many manufacturers prefer to employ specialized manufacturing techniques for Tofacitinib Tablets.

Direct Compression is the most widely used and effective technique employed by modern third-party pharma manufacturing companies such as Taro Pharmaceuticals for this type of highly potent, low-dose drug.

The Tablet Manufacturing Process (Direct Compression)

The procedure eliminates the use of heat and moisture, which is advantageous for sensitive active pharmaceutical ingredients (APIs) and also improves the overall stability and uniformity of the final product.

1. Supplier and Handling of Raw Materials

Tofacitinib Citrate (API) and excipient products (diluents e.g. Mannitol, Microcrystalline Cellulose, disintegrants and lubricants e.g. Magnesium Stearate) are purchased from suppliers that have passed an approval process. The accuracy of weighing and dispensing of each component is extremely important in order to create tofacitinib tablets IP 5 mg strength consistently among all tablets in a batch.

2. Sifting and Blending (The Key Step)

All materials will be sifted well to achieve the proper particle sizes.

The initial mixing of the two materials will take place with a high-volume blender, such as a Double Cone or a V-blender. This is one of the most important times to develop content uniformity, since a very small amount of tofacitinib tablets must be distributed evenly among the much larger mass of excipients.

3. Preparation of Lubricant

A lubricant (typically Magnesium Stearate) is added to the blend and mixed for a short time, gently. The purpose of the lubricant is to help prevent the powder mixture from adhering to the surfaces of the tablet punch and die during compression.

4. Tablet Compression

The lubricated powder mixture is placed in a high-speed rotary tablet compression machine, which uses a set of precisely engineered punches and die sets to compress the powder into uniform tablets. This is also an area where all tablet quality checks will take place, including monitoring variation of the weight of each tablet at the point of being produced, thickness, and hardness, to ensure that they meet the required minimum standards set out within the pharmacopeias.

5. Coating (Not Required But Generally Recommended)

The final tablet cores will usually receive some form of coating (Opadry) for protection against moisture, providing ease of swallowing, taste masking, and helping with the aesthetic appeal of the tablet in regard to branding.

The Power of Third-Party Pharma Manufacturing in India

For marketing organizations, using third-party pharma manufacturing companies is the most effective and flexible path to market. India has a top-class infrastructure that makes this example highly pleasing.

Benefits of Pharma Contract Manufacturing

1. Lower Capital Investment – With a third-party pharma manufacturing company in india, the Brand Owner does not face the large capital expenditures to create a production facility for manufacturing tablets that includes investing in intricate coating and compression equipment.

2. Regulatory Expertise – The third-party pharma manufacturing partners in India have extensive regulatory experience both within India and around the globe. They are already in possession of the necessary pharma manufacturing license in India, and are fully compliant with the stringent requirements of the CDSCO (Central Drugs Standard Control Organization).

3. Quality Assurance – Companies such as Medella Softgel manufacture a variety of different types of formulations, such as tablets as well as softgel capsules, and focus all of their efforts on providing quality control. Clients of these types of Companies have access to properly trained QA/QC Teams and to in-house testing facilities.

4. Scalability and Focus – When the Brand requires a change in the volume of production, the Third Party Manufacturing Partner will be able to prepare for either increased or decreased production without disrupting the Brand’s primary Business Operations, e.g., Marketing, Research, and Distribution.

Regulatory and Quality Compliance – The Indian Gold Standard

The success of Tofacitinib Tablets IP 5 mg manufacturing depends on determined adherence to the Drugs and Cosmetics Act, 1940, and the regulations made thereunder.

Essential Regulatory Requirements

1. Manufacturing License (Form 25/27) – A valid pharma manufacturing license india (Form 25/27) must be held by the facility (Manufacturer) that manufactures the medicine. This pharma manufacturing license indicates that the Manufacturer’s manufacturing facility, equipment, and personnel are capable of producing, where required, i.e., the manufacturer uses the correct equipment and staff to produce the tablets.

2. Good Manufacturing Practice (GMP) – Good Manufacturing Practices (GMP) are required for all medicine manufacturing companies in India as stated in Schedule M of the Drugs and Cosmetics Rules. Additionally, it is preferable to meet the GMP compliance of organizations such as the World Health Organization (WHO) and the U.S. Food and Drug Administration (FDA) for exporting Tofacitinib-based medicines.

3. Technical Staff – Qualified Technical personnel are required to be employed by the Manufacturer for the manufacture of JAKBLOK-5 Tablets, i.e., Production Chemist and Quality Control Analyst. Both these positions require the respective persons to have obtained the required educational & professional training (B.Pharm/M.Pharm) and at least 2 years’ relevant experience in the pharmaceutical manufacturing industry.

4. Product Approval – The JAKBLOK-5 product must be approved by the Central Drug Standard Control organization (CDSCO) before a marketing authorization is granted to the manufacturer to market it. JAKBLOK-5 Tablets includes tofacitinib tablets formulations (IP) 5 mg; these formulations are known to require that the Manufacturer submit a complete set of technical documentation, stability data, and proof (BA/BE) that the generic product is a replica of the brand product.

By partnering with a facility that has already been proven to be compliant with respect to regulations & specializes in making potent molecules, you will ensure the quickest time to market for your product while maintaining the integrity of the product quality.

Also Read: WHO GMP certified Ciprofloxacin Tablets Manufacturers in India